Description

I had a recent project that I have been printing in Ninjaflex on my FDM printer and after testing the D7 printer I thought it would be nice to print some high quality flexible resin prints. The first flexible resin I tried did not do so well so after some more searching I came across the Photocentric3D DLP Resin page. I had looked at their Daylight printers before but did not realize they had started to make DLP (UV) resin. They happen to have Clear (comes in a variety of colors) Flex in the UV / DLP form which is exactly what I was looking for so I ordered a bottle to try. It arrived after a short delay (because it was still being beta tested) in good condition and packed well.

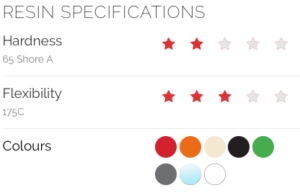

“Flexible UV polymers are ideal for making objects where you want flexibility, but still a hard object. Objects will compress and deflect enough to bend and return. They exhibit low tensile shear properties and some elongation. Objects can be bent and compressed with some force.”

Packing

The bottle was double bagged then wrapped in lots of nice bubblewrap in a large box. The first thing I noticed was the bottle. I like the 1 Liter size and the bottle has a nice no-drip style lid that is easy to pour.

Usage

The first thing I had to do was find good settings for the D7 printer I was testing on. Since the resin was clear I started with the settings I used for the FTD Clear IB resin. It didn’t cure all the way and separated from the build platform so I increased the cure time to 30 seconds (with a 90 second base cure). After that every part I printed cured and stuck to the plate. You need to carefully remove the parts from the plate using a sharp scraper without going to crazy to keep from damaging the delicate (in my case) print. I enabled the Dimming feature on NanoDLP at 35% with 10 Pixel outline for larger prints.

Post Processing

Note: Objects will have full strength only after full cure time. The directions I was given that worked out well are as follows: UV post curing in water for 5 minutes a side, wiping with IPA on a cloth and then curing dry under UV for 2 hours (minus amount of time spent in the water UV bath) gives the best end feel and properties. After I cured the parts for 2 hours they became more stable and flexible. I have a few parts I will be testing to see how it holds up in the near future.

Rating

I would give this resin a 5 out of 5 so far for printability and use.